Nederland home is getting a new addition—a beautiful sunroom.

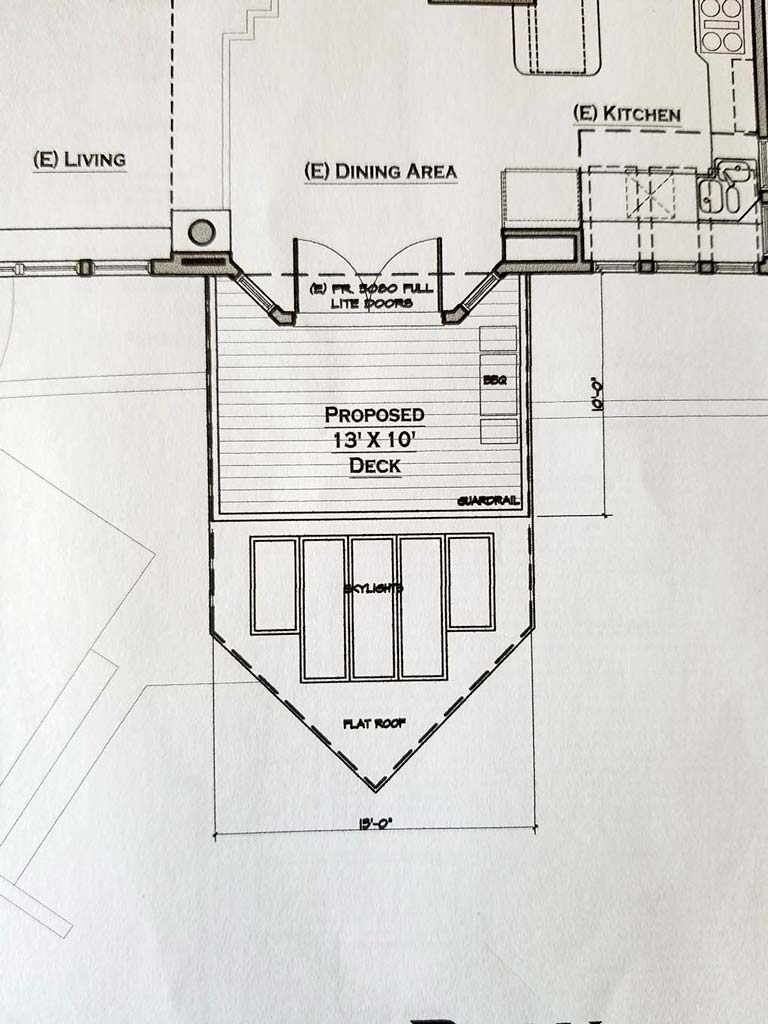

The homeowner had originally contacted us back in June of 2020 with nothing more than architectural plans, provided by architect John Bonvouloir, for a hot tub room addition.

However, the 1st set of plans call for skylights that were not compatible with roof design. The plan had rectangular curb mounted skylights on a flat, triangular roof. The specified skylights could not be installed side-by-side and it would have required a roofers involvement. Also, rectangular skylights just didn’t look right.

I suggested our custom MAGS Bar product instead. We had to make some changes to the plans to add a bit of slope, but the customer was very happy with the new plan of having a full glass roof over this hot tub. This eliminated the need for any roofing work, expanded the visible glass area dramatically.

The aesthetic design was greatly improved with all of the custom glass shapes for this triangular room. It was enjoyable to work hand in hand with the homeowner and the architect to create a room with the overhead glazing system being the focal point of the whole project.

Planning for custom glazing systems with our consultation in the design process was key to this project. We have one very happy customer.

Stan Davies | Northern Field Office Manager

Our crew will install a custom MAGS Bar triangular skylight.

Our system has the versatility to expand the skylight to the perimeter of the space.

Construction is in progress.

The Base:

The Glulam beams offer the ideal base for our very own custom glazing system—MAGS Bar.

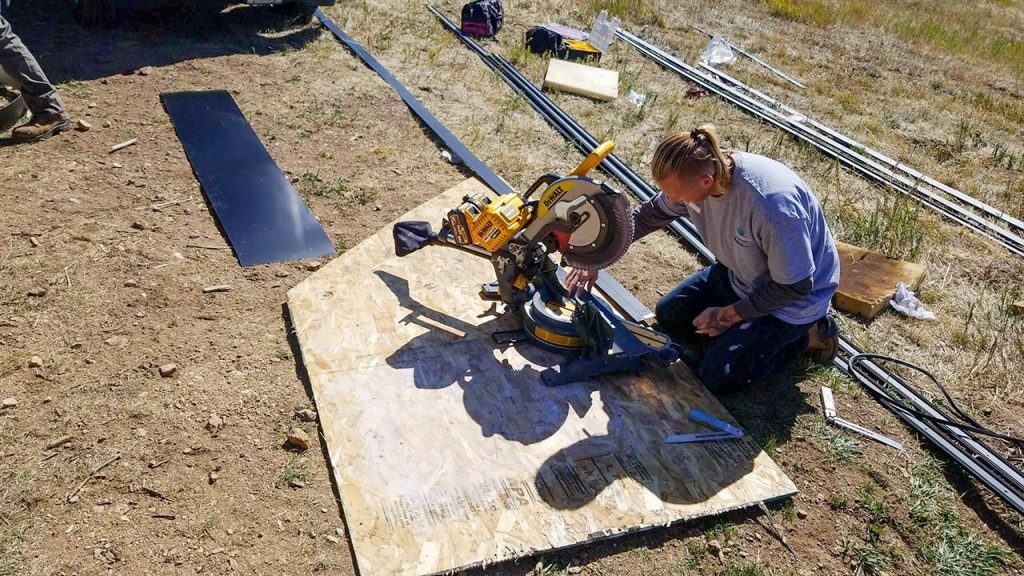

The process is pretty straightforward. Perimeter flashing is applied over an underlayment, then the MAGS Bar base is cut to fit on site and installed.

Glass:

At this point, we are able to obtain exact glass measurements and order the double glazed, Solarban 70 glass units.

We cover the system until glass delivery, typically in 2-3 weeks.

The glass has arrived and construction can proceed to completion.

There are several steps involved with finishing the project—setting the glass, cutting compression bars and beauty caps, manufacturing the custom flashing and sealing the system.

The crew sets up a couple of stations to handle the tasks. One for cutting the aluminum bars and another to create the custom aluminum flashing.

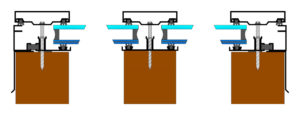

Once the glass is set in place, the compression bars are used to hold it in position and compress the gaskets to form a watertight seal.

The custom flashing, bent to fit, protects and seals the perimeter of the system.

Beauty caps are then installed and structural silicone is applied using the proper techniques—including masking—to ensure decades of weatherproof service.