Another failed fiberglass skylight

The owners of this residence, built in 1922, contacted us regarding their large skylight. This fiberglass skylight, brand unknown, is showing the typical signs of failure—yellowing, staining, and fiber bloom.

Fiber bloom is where the constant exposure to UV rays of the sun erodes the matrix of the material and exposes the glass fibers. If untreated (by coating the surface) it can proceed to the point where replacement is the only option.

The project:

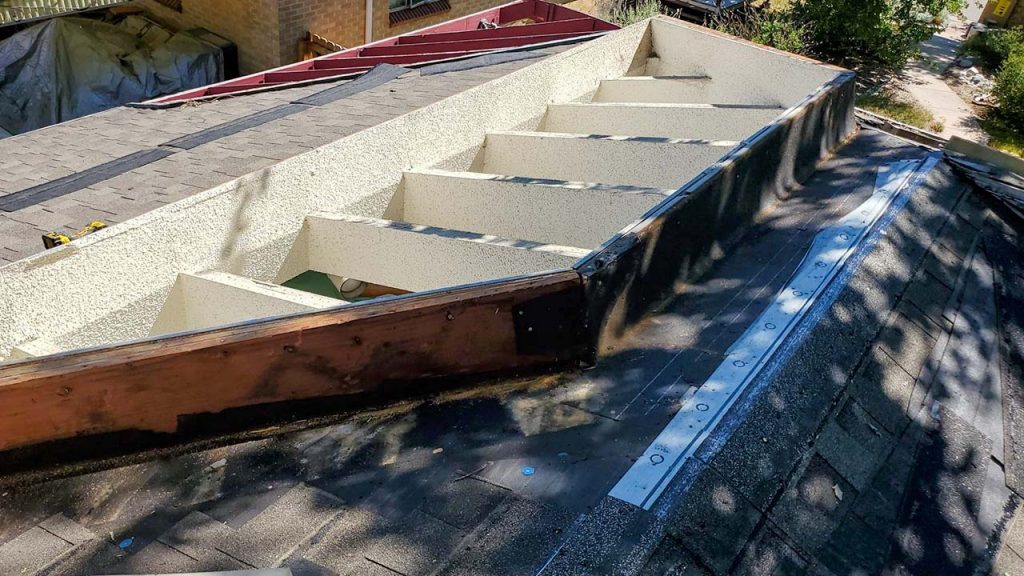

Demo and prep for glass:

The first step, of course, is to remove the old skylight. In this case, given the slope of the roof and the versatility of our MABS Bar system, we also removed the curb.

The next step is to install the framework and flashing. The openings are measured for an exact glass fit and then covered pending the arrival of the glass order.

Setting the glass:

Getting the glass units up to the roof and set in place is an operation that requires a great deal of teamwork and precise handling.

It takes some muscle, also! These large, double paned glass units can easily weigh more than 200 pounds. Experience helps— our techs have handled hundreds.

The finished project:

Low, sleek, modern profile on the roof. Clear sky views. No yellow tinge to the daylight.

Beautiful!

Product used:

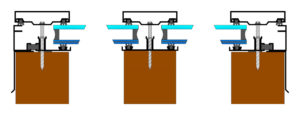

- Skylight Specialists Multiple Application Glazing System—MAGS Bar.

- Solarban 70 Solargray heat strengthened, lowE3 glass.