Replacing Glazing in Sunrooms or Sunspaces

Many factory built sunrooms were manufactured with 30″ wide spacing on their aluminum rafters. They also designed the system to utilize 30″ or 46″ long panes of glass for ease of shipment and installation. A very light duty crossbar held the horizontal edges of this glazing.

We frequently remove these cross rafters and use larger pieces of glass when we need to replace worn out glazing on these systems.

This gives the space a more open feel and has less joints for the sunspace to leak and the structural integrity is not changed.

The Goal:

A glassed-in structure that provides light and warmth with the confidence of a weather tight seal.

Many homeowners and/or contractors have the imagination to design and build the perfect sunspace or greenhouse of their or their client’s dreams.

These designs incorporate glass into the structure, always on the vertical walls and frequently on the overhead roof.

The Problem:

- How to glaze the structure—attach the glass to the building without issues such as leaks.

- How to control daylight—an improper design can create too much heat gain in the summer or heat loss in the winter.

The Solution:

MAGS BAR

- MAINTENANCE FREE (no peeling paint or warping wood).

- ATTRACTIVE 3 1/4″ wide Class 1 black anodized aluminum—can be powder coated any color.

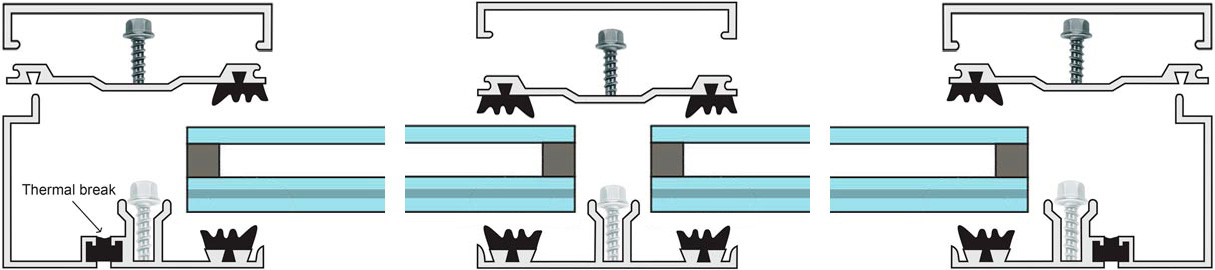

- NEOPRENE glazing seals and thermal break that survive the test of time.

- BUILT IN condensation gutter.

- LOW PROFILE—blends into roof line.

This is a non-structural, all aluminum, glazing bar, with neoprene gaskets, that allows for the simple installation of glass on any structure and with any design.

Click the link above for more information and feel free to call us for design support and price quotes.